There is a serious shortage of glass fibers, the key material of artificial intelligence (AI) semiconductor substrate, and the industry has raised a full warning. With demand soaring, a handful of suppliers, and a prolonged expansion cycle, the supp...

There is a serious shortage of glass fibers, the key material of artificial intelligence (AI) semiconductor substrate, and the industry has raised a full warning. With demand soaring, a handful of suppliers, and a prolonged expansion cycle, the supply crisis is striking the world's advanced semiconductor industries.

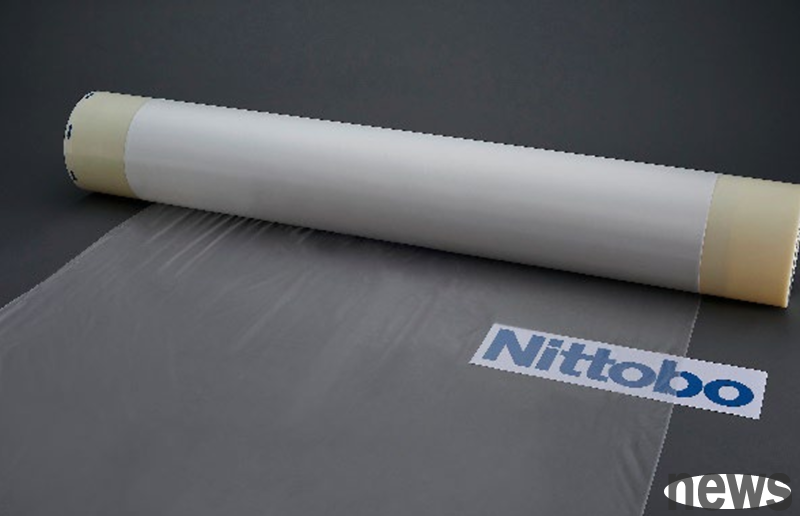

According to industry news, high-level glass fiber cloth T-Glass is a low-coefficient of Thermal Expansion (Low CTE) glass fiber cloth, which is currently in a tight market supply. Nittobo products have increased by about 20% since August, and may continue to increase further. Due to limited supply, manufacturers must divide the goods through allocation methods, and downstream tourists even need to "swallow the goods" to form a glass-standard fabric war.

Several industry insiders revealed: "Japan East products have almost become the industry standard, but the number is limited, so they have to wait in line, and even companies have to fight for themselves." Although Japanese East products have been expanded, the new production line will not be invested until 2027 as soon as possible, and it will be difficult to resolve the gap in the short term.

In addition to Low CTE, the industry has also begun to worry about the insufficient supply of low dielectric constant (Low Dk) glass fiber cloth. As AI servers and high-speed computing platforms introduce large-scale high-speed signal transmission, demand for Low Dk continues to rise, but its current capacity is also limited, and it is expected to become another big bottleneck in the next one to two years.

Taiwan is a global ABF loading town, and large factories such as Xingxing, Nan Electric Power, and Jingxi are all major suppliers of NVIDIA, AMD, and Intel. The industry is worried that if the key materials are relied on the Japanese and Eastern stockings for a long time, even if Taiwanese plating operators are expanded, they may still fall into supply chain risks due to material shortages.

Currently, manufacturers that can supply Low CTE stably are mainly Japanese-East products. Although Taiwan Glass has invested heavily in Low CTE development in recent years, it also stated that the product has been certified by some customers. But the progress of phasor production remains to be observed. Nanya and Fu Qiao mainly enter the Low Dk field, which is used for high-speed, high-frequency PCB and server applications.

Industry insiders pointed out that with the sharp increase in demand for advanced packaging by AI, two high-level materials, Low CTE and Low Dk glass-fiber fabric, will face tight supply at the same time. Whether Taiwan-Bloomberg, South Asia and Fu Qiao can accelerate its entry into the market in the future will become the focus of global supply chains. In addition to waiting for the implementation of the Japanese expansion plan, Taiwanese manufacturers also urgently need to accelerate the promotion of domestic production to reduce their dependence on single overseas suppliers.

AI에 유리섬유 공급난…day 독점 소재에 발만 동동 Extended reading: Japanese-Taiwanese large-scale production T-glass, attacking AI plate material key battleground