2025 Taiwan Electric Technology Forum Taipei venue lecture, Zhang Xiaoqiang, senior vice president and deputy co-operating manager of business development and global business, said that the semiconductor industry is undergoing a very important strat...

2025 Taiwan Electric Technology Forum Taipei venue lecture, Zhang Xiaoqiang, senior vice president and deputy co-operating manager of business development and global business, said that the semiconductor industry is undergoing a very important strategic change. Based on his 30 years of experience in the industry, he is still full of confidence in the future of the semiconductor industry. To understand the market, the most important thing is to focus on long-term development trends, which are determined by basic technology, business or economy, rather than short-term market trends.

Zhang Xiaoqiang pointed out that the hottest word in semiconductor industry is AI. From a semiconductor perspective, 2024 is regarded as the natal year of AI. AI applications have had a huge impact on all semiconductor fields, and this trend is expected to continue to be very strong in 2025. Therefore, from the perspective of semiconductor applications, the main driving force of AI is at the leading process points, such as 5 nm, 3 nm, and the future 2 nm. At the same time, advanced packaging technologies such as CoWoS are also very important.

In addition, the largest market source of AI is high-performance computing (HPC). Basically, the most important basic factor for AI to lead future semiconductor development is energy efficiency. Due to the continuous advancement of semiconductor process technology and the evolution of design architecture, energy efficiency will increase by three times every two years (3X), making energy efficiency considered the most important foundation for future AI development. In particular, many applications of AI are currently in the cloud and may be expanded to the edge in the future, so that the future semiconductor environment will be completely driven by AI. AI applications will flourish in all aspects.

In terms of the entire market and application trends, high-level models of smart phones will adopt a large number of leading technologies. However, even for the most advanced mobile phones, energy efficiency is still the most need to be improved, and the impact of comparison applications is still strong. As for the automobile, although the overall automobile market is relatively soft, the use of automobiles for advanced processes is accelerating in semiconductor applications. This is mainly due to the advancement of automatic driving function. Moreover, most of the self-driving chips currently still use 12-nanometer or 8-nanometer processes, but will accelerate into 5-nanometer or 3-nanometer processes in the future. Moreover, more and more electronic devices for vehicles are even seen as a previous step in robots. The manufacturing process of electric vehicles is becoming more and more electronic, just like the manufacturing of smart phones.

In terms of robots, real robots, especially the currently popular humanoid robots, are the trend of the future. Many car manufacturers are extending the concept of cars to the robotics sector. Humanoid robots require a high level of intelligence, which comes from advanced processors. They require a lot of complex electronic parts and advanced software to implement functions, such as mimicking human hands-on. Therefore, future robots need to achieve 10 times the progress, including price, power consumption and computing power. This will require more advanced process technology. The network communication technology standard increases by about 10 times the frequency width every decade, which means more computing power is required. For example, from Wi-Fi 6 to Wi-Fi 7, more investment is required to provide higher bandwidth and more features.

The technical route diagram of TECHNO is predictable and customer-oriented. They will announce their technology in advance for the next two or three years to allow customers to plan their products. In terms of N3 production, the lecture has entered the third year of mass production. There are continuous derivative processes such as N3E (enhanced performance), N3B (enhanced performance and density), and future N3X (higher performance, higher frequency) for HPC.

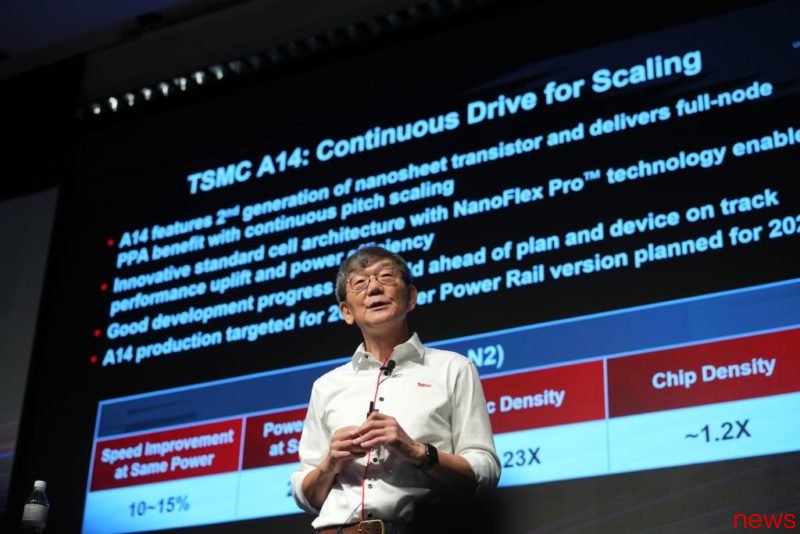

The next N2 process customers have very high utilization, the first year was twice that of N3/N5, and the second year was four times that of N2. More and more academic research has begun to adopt the most advanced processes. As for the newly developed A14 process, it is expected to enter a large amount of production by 2028. Compared with the previous generation N2, the A14 will have a 10% increase in efficiency, a 30% increase in energy efficiency, and a logic density increase of more than 20%. Improvements in energy efficiency and logical density are very important for AI and HPC applications. The A14 also combines design and technology innovation.

In addition, in terms of A16 processing, it is the first generation of processes that use Super Power Rail (SPR) technology. SPR places the power network on the back of the wafer. The research and development of A16 has been progressing smoothly and is expected to enter mass production in the second half of 2026. And the A16 will bring many advantages to AI and HPC. As for future transistor technology, the TEEA research and development team is exploring innovative technologies such as GAA (Gate-All-Around). For example, inverters made with C-Gate (Compound Gate) material have shown excellent performance. Low-dimensional or even 2D materials are also being studied in materials to provide more opportunities in the future.

In order to meet the needs of AI computing, more computing cores are needed, which has given rise to 3D integration technology. TEK has introduced the concept of System-on-Wafer, which uses the entire wafer as an interposer, which can bring a 40-fold integrated size increase compared to traditional packaging. At the same time, in order to improve energy efficiency, photoelectric integration is an important direction in the future. Currently, optical conversion occurs at the top of the cabinet. The future goal is to integrate optical components and electronic chips into the packaging level. This brings about 2 times the energy efficiency improvement.

Finally, in addition to the most advanced logical processes, special process technology is also very important. Zhang Xiao has strongly adjusted, which includes sensors, power management, pivic technology, radio frequency (RF), and embedded memory. Embedded memory, especially embedded non-development memory (eNVM), is increasingly integrated into logical chips. Mainstream eNVMs include RRAM (RM) and MRAM (Magnetic friend), which are compatible with logic processes and are easy to miniaturize. These techniques enable memory storage cells to be embedded in a logical chip.

In terms of power management technology, high-voltage technology is very important. Introducing high voltage technology to a smaller process point can significantly reduce power consumption (28%) and increase logical density (40%). The development of power management technology of Telco also focuses on improving power supply capabilities.